Call Today! 1-860-677-6711 - Delivering Maximum Performance with Precision-Engineered Hinges, Latches & Fasteners Since 1964

Call Today! 1-860-677-6711 - Delivering Maximum Performance with Precision-Engineered Hinges, Latches & Fasteners Since 1964

1. Forces and hole diameters (sizes)

The size of the quarter turn fastener can be determined by the occurring forces (see table of forces), by existing hole sizes or aesthetics.

2. Standard heads and material of the Stud

Once the size of the stud has been selected, the shape of the head and the material must be chosen. For special heads take our resume on pages E-5+6. To determine the length of the stud see page E-4.

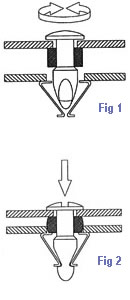

3. Securing the Stud

You have to choose the best method of securing the stud at the loose part. For temperatures up to 90 C the standard washer “R” is adequate and the most popular method of retention. For temperatures exceeding 90¡C the conical wire spring or circlip are recommended.

4. Fixing-method for Spring Clips

The Clip is the least expensive item and dependant upon customer preference and mounting position. The Clip can be assembled using rivets, spot welding, screws, clip-ins, slide-ons and angle-plates. To ease a conversion to the BI-FIX quarter-turn system, we offer spring-clips whose hole patterns correspond to those of other producers.

5. Choice of Stud

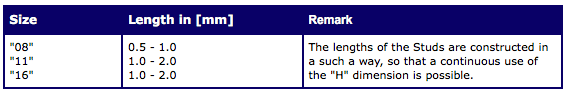

All series are available in any grip length, standard items are graduated as listed. Specials are available to customer requirements:

Copyright © The Paneloc Corporation. All Rights Reserved.